DEFINITION OF CALIPERS

Calipers are extremely versatile measuring tools. Most callipers 12"/300mm and under can perform OD, ID and step measurements and normally have a depth rod for measuring deep recesses. They are available with plastic, stainless steel and carbide jaws to match your measurement requirements and are available with either vernier, dial or electronic displays. Inch dial calipers are normally graduated in .001" and have either .100" or .200" range per revolution. Metric dial calipers are normally graduated in 0.01mm or 0.02mm and have either 1.0mm or 2.0mm range per revolution.

TYPES OF CALIPERS

STANDARD ELECTRONIC CALIPERS

Standard Electronic Calipers are available with or without digital output. They are used throughout the industry due to their rugged design and easy-to-read display

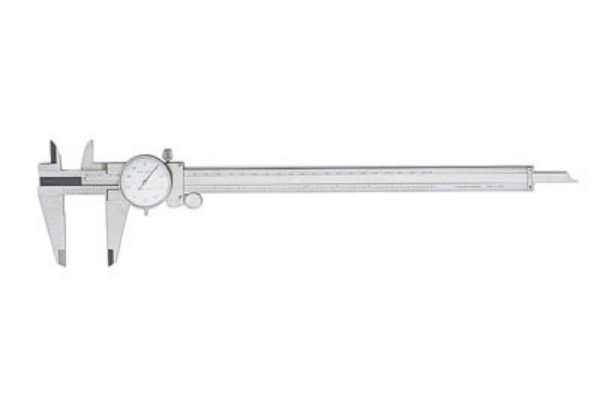

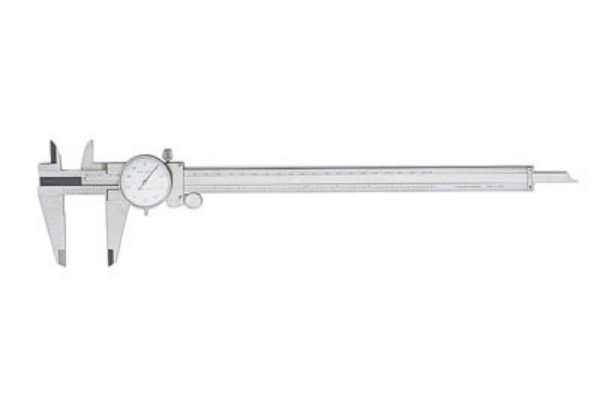

DIAL CALIPERS

Dial Calipers are an extremely versatile measuring tool. They can measure OD, ID, steps, and normally have a depth rod for measuring deep recesses. They are easier to read than vernier calipers and are available in inch or metric models.

VERNIER CALIPERS

Vernier Calipers are available in inch, metric and inch/metric models. Smaller vernier calipers have largely been replaced by dial or electronic calipers.

PLASTIC CALIPERS

Plastic Calipers are available in electronic, dial or vernier configurations. They are designed to be used when a non-marring jaw is required, such as measuring X-rays, plants, animals or other fragile items and high accuracy is not required.

LOW-COST ELECTRONIC CALIPERS

Low-cost calipers provide an easy-to-read tool when high accuracy or digital output is not required.

SOLAR ELECTRONIC CALIPERS

Solar Electronic Calipers eliminate the problem of battery replacement/disposal and the additional costs. They are available with or without digital output. IP67-rated waterproof models are also available.

WATERPROOF CALIPERS

Waterproof Electronic Calipers are designed to be used in harsh fluid or dust environments. They are available with or without digital output. They are currently available in IP65 to IP67 protection levels. IP67 has the greatest waterproof rating and can be subjected to flood coolant.

THE FUNDAMENTALS OF IP STANDARDS

International Protection (IP) Standards are a good way to compare dust and water protection levels of different tools. “IP” stands for Ingress Protection (An enclosure spec) or International Protection.

The IP codes are normally two-digit codes, such as IP65 or IP54.

The first digit represents the amount of foreign objects (or dust) that can enter the enclosure.

The second digit represents how watertight the enclosure is. As shown in the table below, the water protection spec is a good gauge of how a tool will hold up against coolant spray on a machine tool.

| Protection Level |

Protection against human touch and foreign matter |

Protection against water | ||

| Type | Description | Type | Description | |

| 4 | - | - | Splash-proof type | Has no harmful effect from water splashes coming from any direction |

| 5 | Protection Against Dust | Protection against harmful dust (penetration of dust not affecting the function is considered OK.) |

Jet-proof type | Has no harmful effect from direct water jets coming from any direction |

| 6 | Dust Sealing | Protection against the penetration of dust and perfect protection against human touch |

Water-resistant type | Letting no water in from direct water jets coming from any direction |

| 7 | - | - | Watertight type | Letting no water in under specified conditions if submerged |